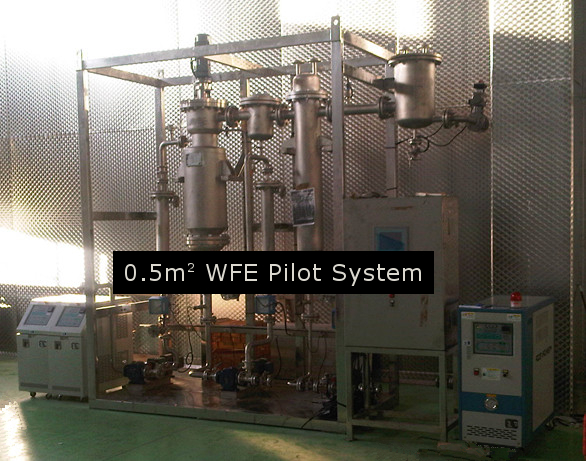

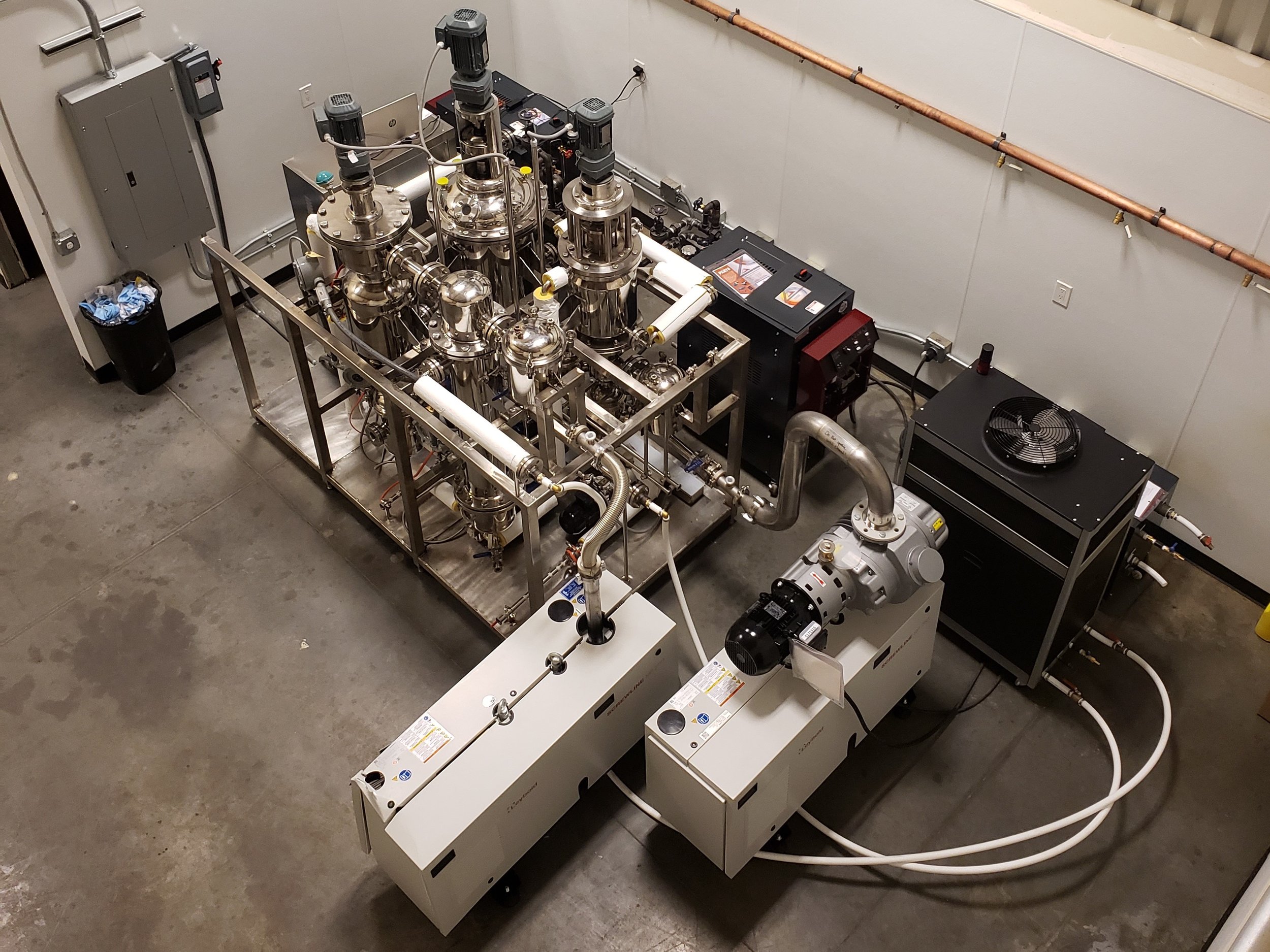

Vobis manufactures wiped film evaporator systems (also called agitated thin film evaporators) for high viscosity, heat sensitive, foaming or fouling applications, for which either high heat or mass transfer are required. Our systems offer minimal process fluid hold up, short residence time plug flow wiped film evaporation. Our WFE evaporator systems can range up to 100m2 heat transfer surface area.

Our wiped film evaporators induce a mechanically agitated thin (wiped) film with a high surface renewal rate against the interior heat transfer surface while the evaporator is operating under vacuum, so that the product sees primarily the equilibrium conditions inside the evaporator. Feed material is tangentially distributed onto the interior wall of the evaporator, and the wiping blades smear this liquid against the heated surface in a rapidly renewed thin film surface with heat on one side and the vacuum conditions on the other side of the film. The residence time of this material inside the wiped film evaporator is a few seconds before the concentrated bottoms exit the evaporator. Evaporated volatile components exit the wiped film evaporator and are condensed in a separate chamber (unless micron vacuum levels are required to reduce heating conditions further; for more information regarding this alternative, please see our molecular distillation section).

The separation of lights from heavies in our wiped film evaporation systems is usually accomplished in a single pass in a plug flow manner to minimize product heat exposure. Either a great deal of volatile components can be evaporated, or the rapid surface renewal and large delta T provided by the material being wiped across the heat transfer surface can be used to deliver high mass transfer rates to reduce volatile components to low PPM levels without degrading heat sensitive actives.

Vobis wiped film evaporation systems offer a unique means to process heat sensitive materials which can also be viscous and/or fouling. These systems are constructed of various metallurgies including a broad range of SS alloys, hastalloy, duplex steels or titanium and typically include the primary peripherals such as vacuum system, pumps, piping and controls.

Our wiped film evaporation systems are especially appropriate for applications which are:

High viscosity, tens of thousands of cP

Heat sensitive products or actives

Foaming, which are normally difficult to separate

Fouling, which the high surface renewal rate helps to resolve

Typical application examples include:

Lecithin drying and glycerin recovery and purification

Solvent stripping from foods

Concentration of sugar solutions to 99.5%

Recycling of solvents from greases and oils

Hemp distillation

Removal of solvents and monomers from polymers, either natural or synthetic

Reaction and removal of condensates from polyesters or capralactam from nylon 6

Purification of essential oils

Concentration of enzymes, fruit and vegetable purees, proteins, vitamins, and biological solutions